Man your Cages

For the past few hundred years along the U.S. coastline, oysters have been under attack. Current efforts to restore oyster reefs are bringing renewal and protection to this humble mollusk, which in turn protects against the erosion of our coasts and waterways. In terms of farming oysters, rigorous methods and ongoing research are required in maintaining this crop and bringing it to our tables. Oysters are abundant in the minerals and nutrition they provide while offering their distinctive brand of culinary delight to their host of fans.

Methods of Farming

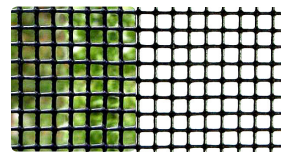

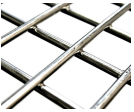

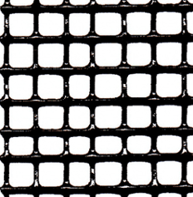

One of the most common methods of cultivation is cage-raised oysters. Many of our favorites, indeed a majority, are bred this way. Happily, shell-fish farms are high on the list of sustainable methods of farming--pleasing environmentalists and purveyors. Some methods of cultivation are rack and bag, tray, floating, and buoy suspension.

Cage-raised Oysters cultivated above the bottom of a bay are:

- Kept cleaner

- Protected from predators

- Thinner-shelled

- Resulting in better yields

- Sometimes mixed in their cultivation--cage-raised above, then transferred to the bottom of the bay toward the end of their development--creating stronger shells

Oysters raised on the bottom of the ocean floor are:

- Similar to how oysters grow in the wild

- Stronger shelled

- Vulnerable to mother nature

- oysters may suffocate under the bottom of the bay

- suffer attack by predators, such as the oyster drill or the New England dog whelk, commonly found in intertidal areas of Rhode Island

- frozen in ice and taken out to sea

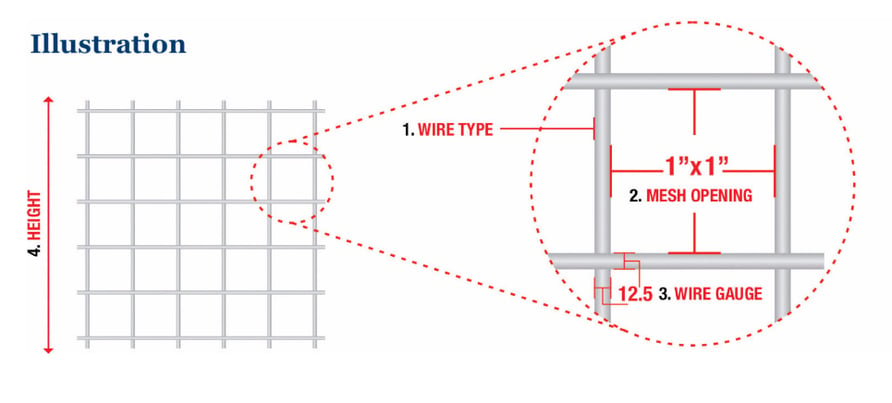

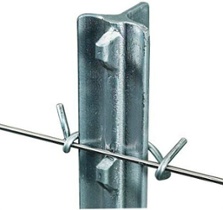

Methods used to raise oysters on the bottom of the ocean are many and may depend on geography--beach versus bay, also the local regulations, predators, and weather. Louis Page will stock your enterprise with a variety of necessities, be it 12½ gauge galvanized after mesh, 14 or 16 gauge vinyl coated wire mesh in ¾" x ¾", 1" x 1", 1½" x 1½" openings or hardware cloth, which comes in ½" x ½" and ¼" x ¼" openings. The wire mesh heights typically used by the oyster industry range from 12" to 48".

Learn from a farmer in action:

An Oyster is a Cleaning Machine

One adult oyster filters 30 to 50 gallons of water every day. Pollutants such as nitrogen, phosphorus, and carbon dioxide are filtered from coastal waters by oysters, rendering them clearer and cleaner. The presence of oysters helps to control algae as they build up ecosystems by attracting various types of sea life. A keystone species is central to keeping an ecosystem functioning and as such, oysters are relied upon by other species in maintaining biodiversity along coastlines and in estuaries.

Erosion Solutions

350 square miles of Oyster Reefs--that was the approximate number of oyster reefs occupying the waters around the city of New York in the 1600s. Oysters were plentiful and by the 1800s oyster carts were the hot dog stands of the day. At the time, half of the world's oyster population was found in that area. 85% of oyster reefs have disappeared around the world in the last 100 years, due to higher ocean acidity, over-harvesting, and disease. By the early 1900s, the oysters were gone, eaten. Wouldn't you know it, these reefs control erosion and act as buffers from high waves during storms; hence, major cities are protected by them. Oyster reefs act in a sponge-like way, drawing the energy out of passing waves, and are actually more effective and inexpensive than steel walls and wooden bulkheads, which increase sand erosion ahead of these artificial structures.

Military and environmental groups are working together to plant miles of oyster reefs along the coastline of New Jersey, which has suffered much storm damage in recent years. Other reefs are being built along the East Coast as far south as Florida. Amazingly, every coastal state in the U.S. is using oyster reefs for the buffering of storms and/or water amelioration. As they struggle to survive, it is best to leave these wild oysters and their reefs to their important work, and rely on farmed oysters for consumption. Take a look at this article to learn about recent strides that are being made.

The Rebuilding

There is a project afoot to rebuild the oyster reefs around the New York Harbor in the next twenty years. The Billion Oyster Project sets its sights on building 100 acres of oyster reefs which will become home to a billion oysters by 2035.

Oyster larvae, known as spat, naturally attach to oyster shells and after many generations (with some assistance) build up the reef. Restaurants are returning oyster shells so that after being

Nutrition

A single medium-sized raw oyster contains roughly 5 grams of high quality and complete protein, as well as these life-saving and life-enhancing vitamins and nutrients:

Zinc--the humble oyster is brimming with the stuff. Zinc is important for cell division and is responsible for the function of red and white blood cells in our bodies. It is indispensable for physical performance, energy levels, body composition, and maintaining ideal hormone levels. Zinc is also an antioxidant--busy stabilizing stress levels and fighting aging. Low levels of zinc are known to cause reduced libido and infertility.

Potassium--occurs in high levels in oysters: it helps lower blood pressure, relax blood vessels, and provide good cholesterol.

Vitamin D--essential for absorbing calcium and promoting bone growth. Low vitamin D is associated with breast, colon, and prostate cancers, heart disease, depression, and weight gain.

Vitamin E--aids in making cellular membranes strong and flexible.

Vitamin B12--oysters are an excellent source. B12 regulates the metabolism and formation of red blood cells while maintaining the central nervous system, brain health, and development.

Iron--the main component of hemoglobin, which is a protein that carries oxygen in the blood. Iron is crucial to red blood cell production and therefore to vitality. In its fight against anemia, iron stimulates the nervous system, supporting muscles and energy levels, cognitive function, and stomach health.

Copper--regulates iron, ensures appropriate enzymatic reactions, enhances the health of connective tissues, hair, and eyes. It regulates heart rhythm, balances thyroid levels, enhances red blood cell production, and reduces cholesterol. Amino acids and vitamins are metabolized by copper. The body does not manufacture it and therefore must be added through diet--consult an oyster.

Manganese--a powerful antioxidant. Creates essential enzymes for building bone, maintaining bone structure, and bone metabolism. Assists in the formation of connective tissues and absorption of calcium while regulating sex hormones, healthy blood sugar levels, and the metabolism of carbohydrates and fats.

Selenium--an antioxidant, a catalyst for active thyroid hormone production, necessary for sperm motility, may prevent miscarriage and is thought to be a mood stabilizer. Healthy levels are linked to reduced cancer and heart disease risk.

Yet as always, consume oysters in moderation as they are so vitamin-rich, they can result in mineral overdose, and always buy them from reputable sources. Consume oysters as a preventative and not as a medical treatment, especially in the case of established heart disease. And the martini you might add to the mix? Well...life has its trade-offs.

Louis E.Page Inc. is committed to sourcing and delivering the finest fence and mesh supplies available to do the important and rigorous work of cultivating oysters. You can be assured that the products we sell are the best-engineered on the market today.