Planning, Calculation, Installation

Let's begin with a drawing as an introduction to calculating the needed materials for a fence project:

Guidelines to help you install your wire fence

If you find yourself asking how many feet of welded wire or mesh do I need, this article can help you. Don't forget about figuring out how many posts you need in advance - a fence without posts isn't a fence!

The Plan

1. Determine the kind of fence you will need, based on the requirements of the application - the purposes and needs of your particular situation.

-

Type: You can choose from a wide variety of fences and meshes.

-

Size: Different heights, size, and spacing of mesh openings, finishes, and gauges of wire fence are available to fit every use.

2. Create a plan for the fence project design. Establish where the corners and ends of the fence are to be located.

3. Calculate the amount of fence and posts (end, corner and line posts) needed for the job. Don't forget to add any gates that are required to complete the project.

-

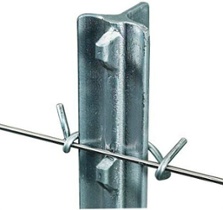

Type: Wood or studded T posts can be used to hang the fence.

-

Spacing: Figure line post spacing at 8 to 10 feet apart.

And Installation

1. Fence posts

-

Make sure end, corner and gate posts are placed deeper in the ground than line posts for more holding power. Corners and ends may need bracing, depending on the type of fence used.

-

Be sure to tamp and level wood posts before moving on to the next step.

-

T posts can be driven into the ground using a manual post driver with handles. The driver eliminates the potentially dangerous use of an unwieldy sledgehammer.

2. Attaching fence posts

-

Wood posts - galvanized slice-cut staples can be used. These are available in ¾", 1", 1¼", 1½", 1¾" and 2" sizes.

-

Studded T posts - metal clips are provided with each post to securely hold the fence.

3. Stretching the fence

- The appropriate amount of tension depends on which mesh is used. Woven wire fencing, especially high-tension field and deer fences, requires a lot more tension than welded wire fences.

Please! Print this handy Louis E. Page Fence Calculation Reference Page to help you with your measurements.