💼 Negotiating with Confidence: How to Stand Your Ground and Win Trust

You see, I absolutely understand those moments when you’re faced with a client asking for a lower price or trying to expand the scope of work. I’ve been there! And I’m super passionate about helping contractors like you handle these situations with confidence.

Let me share three things I’ve learned about negotiating that can make such a difference in your business:

1. Your Worth Shows in Your Work

When someone asks, "Can you do it for less?" remember—you bring real value to every project. Instead of jumping to reduce your price, share what makes your work special. Maybe it’s how you take extra care with installation, or how you use premium materials like our top-quality wire mesh that lasts for years.

2. The Power of Taking a Breath

You know what’s amazing? Sometimes the best response is no response at all. When a client questions your pricing, try taking a calm pause. Give them space to think. Often, they’ll talk themselves into seeing the value you offer.

3. Standing Strong (While Staying Kind)

It’s wonderful to be flexible where you can—maybe with timing or project phases. But some things, like quality materials and proper installation, need to be non-negotiable. Being clear about this actually helps build trust with your clients.

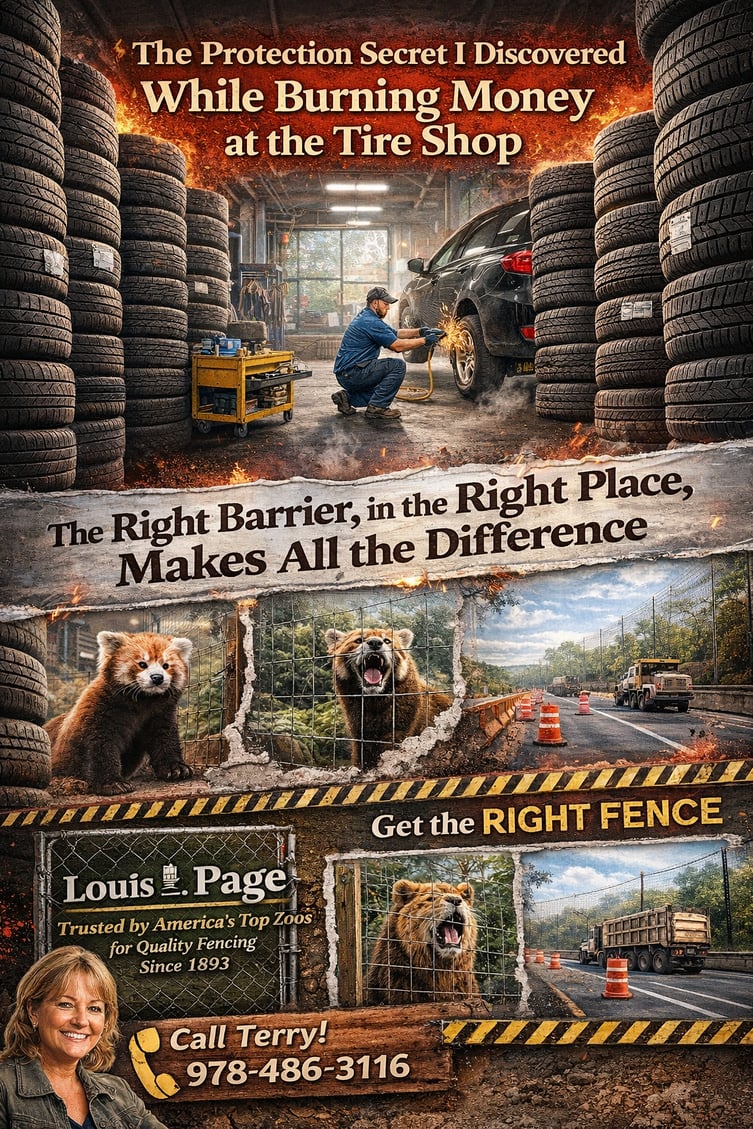

We’re Here to Help You Deliver Excellence

I’m very proud to say that here at Louis E. Page, we love helping contractors like you. If you’d like to talk about fencing solutions that can help you deliver excellent value to your clients, our fence expert Terry would be happy to chat. Just call 978-486-3116.

Here’s to creating strong partnerships,

Debbie Page

P.S. Planning a spring construction or renovation project? Terry’s phone is gearing up for spring—grab a spot now to ensure you get the expert guidance you need!