❄️ Weathering the Storm: A Tale of Endurance and Resourcefulness

I recently finished reading Ranald Bannerman by George MacDonald, and one story from the book felt like it was calling to be shared. It’s a tale of resilience, resourcefulness, and staying calm in the face of unexpected challenges—something we can all relate to in both life and business.

A Blizzard in the Highlands

In the story, Ronald and his father find themselves caught in a blizzard in the Scottish Highlands during a three-mile journey on horseback. The snow was thick, the wind relentless, and before long, their horses slipped into a ditch and bolted back home, leaving them stranded in the dark.

Faced with bitter cold and no clear way forward, Ranald’s father relied on his quick thinking and knowledge of their surroundings. They stumbled upon a stack of peat—a resource the Scots traditionally used as fuel. Ranald’s father hollowed out a space within the peat stack to create shelter, providing some protection from the biting wind and snow. It was far from comfortable, but it kept them alive.

And I loved how Ranald’s father found humor in the situation, even though he knew their lives were at stake. Around 1:00 a.m., help arrived. The horses had returned to the barn, alerting the farmer to start a rescue mission.

Lessons for Life and Fencing

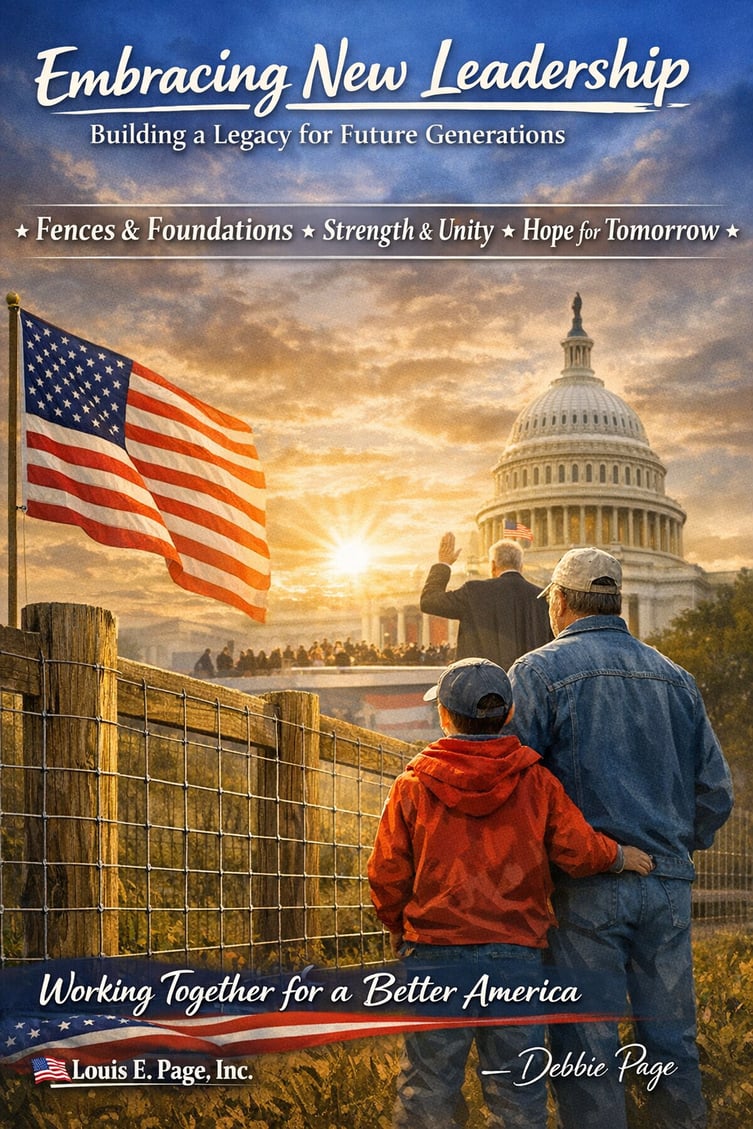

This story reminded me of the importance of preparation, quick thinking, and community. At Louis E. Page, we often encounter our own version of “blizzards”—unforeseen challenges on fencing projects. But like Ranald’s father, we focus on staying resourceful and finding solutions, even when conditions seem daunting.

Whether it’s ensuring your fencing materials stand up to harsh weather or assisting you with a tricky installation, we’re here to guide you through the storm. And just like that farmer coming to the rescue, we’re only ever a call away.

We’re Here to Help

If you need help, reach out to Terry, our fence expert, at 978-486-3116. She’ll help you find your way to the right materials and solutions.

Stay steady and safe,

Debbie Page