The Right Tools

The wonderful folks from Bekaert step in to help renew an extensive field fence with high tensile woven wire and barbed wire. A classic demonstration using a gripple, a stretcher bar, and a new-fangled staple gun.

800-225-0508 Mon-Fri 8:30 - 4:30 EST

Free Quote: Email | 866-328-5018 (M-F 8:30-4:30 EST)

Call: 800-225-0508 | Free Quote

November 23, 2020 | by Joe Morrell

The Right Tools

The wonderful folks from Bekaert step in to help renew an extensive field fence with high tensile woven wire and barbed wire. A classic demonstration using a gripple, a stretcher bar, and a new-fangled staple gun.

Topics: woven wire, galvanized, how to

December 24, 2019 | by Joe Morrell

Expansion

Frost heaves are caused by water that is drawn up through deep unfrozen soil to varying depths of frozen soil beneath ground level. A horizontal ice lens grows particularly in clay-type soil, collects below the frozen soil, and then expands as it freezes, slowly pushing soil, as well as rocks and debris, upwards.

Courtesy of Wikipedia Commons

What Lurks Below

Certain types of soils are not a concern. Gravel and sandy soil are not susceptible to the exchange of moisture that create frost heaves. Very thick clay soil is also immune. Also, where frost only penetrates the soil an inch or two there is no need to be concerned about frost heaves, such as on the west coast and the southernmost parts of the U.S.

However, where freezing goes deeply into the soil, your fence posts (and the footings of your deck) are subject to this upward pressure. The concrete in the fence post's base is an excellent conductor of heat and attracts moisture which can form an ice lens around the concrete base, rendering it susceptible to movement. A pressure-treated wooden post is not a good conductor of heat, particularly when wrapped with plastic or coated with tar; this helps prevent the up and down movement of the post.

General Guidelines

Most likely, setting a post a couple of feet, and up to 5 feet, is required to offset this issue. Your local town building inspector probably has guidelines for the best depths for fence posts in your particular area. If you dig a hole that's wider at the top in a V shape, you'll have a problem. The smaller bottom of the hole will provide little resistance for the upward pressure of the moisture and what follows it. A hole dug in the shape of a bell (wider at the bottom) is better, fill it with:

Bring the concrete or fill within a few inches of ground level and fill the rest of the way up with tamped-down dirt. Concrete footers are the best bet for offsetting the pressure that works on the fence above the frost line. Some experts recommend an insulating pad of Styrofoam about 2 inches thick beneath the footer. However, when all is said and done, setting your posts at least 2 feet underground is a safe bet.

Frost heaves can also push up plants and expose roots to damaging wind and cold, not to mention poorly prepared roads and sidewalks.

Here's a thorough going-over of the process with a variety of scenarios:

Do you have expertise in your area on the subject of frost heaves? Please share your insights or recommendations below.

Topics: concrete fence posts, wood post & rail fence, how to, posts, Fencing Tips

February 6, 2017 | by Debbie Page

First, a little background...

Merriam-Webster's Online Dictionary defines wire gauge as any of various systems consisting of a series of standard sizes used in describing the diameter of wire. It all starts with heavy coils of large diameter wire called rod made in a rolling mill. The rod is then shipped to a wire manufacturing mill. To make the wire used in wire fence and mesh, single strands are "drawn" through a series of increasingly smaller dies or plates and reduced to a specific gauge/diameter. The gauge is determined by the wire's final use - single strand wire, welded wire mesh or woven wire fence. Heating of the wire is not required in the drawing process.

In this article, we'll answer the following questions:

Wire Gauges Over Time

There have been several different gauge designations since the process outlined in the introduction was innovated.

Numbers have been used to designate wire diameter since 1735. They originally referred to the number of draws used in the process. The first draw was called 1 gauge, the second 2 gauge, the third 3 gauge, on down to the final draw of the thinnest wire being made.

The amount of "draws" required in the process determines why thick wires have a lower gauge number compared to thin wires. 9 gauge wire is thicker than 14 gauge because it requires fewer "draws" than 14 gauge.

>We offer expert advice on fencing free of charge for all of your fencing projects. Please feel free to call us at (866) 328-5018 or you can request a free quote by clicking the button. If you aren't quite ready to talk fencing yet, simply download our free catalog.

Need some inspiration? Check out these recommended articles and more:

Topics: wire fence, welded wire fence, how to, wire gauges

June 20, 2013 | by Debbie Page

A Helpful How-to on Splicing

Do you have a woven wire fence that needs repair? Has this ever happened to you?

Watch this video and learn a couple of different ways you can splice a woven wire fence.

Have you discovered other helpful techniques for mending and splicing woven wire fences you'd like to share?

Topics: woven wire, how to

May 4, 2013 | by Rick Hoffman

Safe and Simple Installation

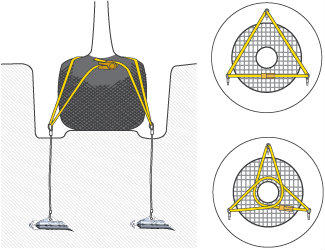

Don't worry, we believe in freedom of movement for all ducks and no ducks are ever harmed using DUCKBILL® EARTH Anchors! So, you may ask, “What are DUCKBILL anchors and what are they used for?” Glad you asked!

The anchors work very much like toggle bolts in soil. They are driven into the ground with no holes, no digging, and minimal soil disturbance creating a safe and environmentally sensitive installation. The anchor body is driven into the soil with a reusable drive steel (drive rod). Once the anchor body is placed to the proper depth the drive rod is removed. With an upward pull, the anchor tendon rotates the DUCKBILL into a perpendicular “anchor lock” position in undisturbed soil resulting in superior holding capacities. Plus, there are no potentially hazardous metal eye bolts or hooks above ground to trip over or for the lawnmower to hit.

DUCKBILL Earth Anchors are used in a wide variety of applications.

There are reported losses of millions of dollars per year due to theft. DUCKBILL anchors reduce theft and unwanted movement of objects like:

Helping Trees Establish Themselves

DUCKBILL Tree Guy Systems are perfect for keeping trees vertical and limiting motion, letting the roots establish themselves for quicker, healthier growth. It protects trees from being blown over and killed by the wind. Easy, safe installation means more trees anchored per hour and a more professional appearance. When the guy systems are not possible or desirable, such as in playgrounds, parks, or where sidewalk plantings are required, use the Root Ball Kit. It is specifically designed to hold the tree’s root ball firmly in place, with only the tree protruding above the ground. Each kit comes with three anchors with D-ring and one strap with a hand ratchet.

DUCKBILL Earth Anchors are used worldwide to secure any object that can be stolen, moved, or blown down like:

300 to 5,000 Pounds Holding Capacity

Anchors are available in 4 Aluminum alloy models and 3 Galvanized ductile iron models (for very hard soils). The anchors range in holding capacities in normal soil from 300 to 5,000 pounds. The anchors are designed to function in the total range of soils. Normally, wherever you can drive a stake or drill a hole, you can use a DUCKBILL.

The next time you need to secure something to the ground, consider using a DUCKBILL earth anchor. They are safe, strong, and easy to install, and are designed to work in a multitude of applications. Can you think of any additional ways DUCKBILL anchors can help you feel more secure?

Topics: duckbill earth anchor, how to

CUSTOM QUOTES

No minimum order required

Farms & Fields | Homes & Gardens | Parks & Public Spaces | Construction Sites

Serving America's Fencing Needs Since 1893

Thank you so much for your prompt and explaining emails and phone calls. I am very happy with the order and follow through. You are very much on top of your game and the service is beyond excellent.

Thank you for your outstanding service and delivery time! I place orders all over the country, and sometimes it takes three or four days just to get products ready for shipment. NOT AT LOUIS E. PAGE. You guys are on it.

Congratulations on this milestone! When our clients request mesh or welded wire, you are our go-to source! Thanks for being a leader in the industry & one we can reliably count on!

Thank you, we received the fence and appreciate the good service from Louis Page. We will call next time we need fence!

I have been dealing with Louis E. Page, Inc. for over 20 years. I build shooting preserves. We will be purchasing all of the Bird Pen materials from you. I just want to thank you for the years of great service. Your products are all High Quality and you always have what I need to complete my projects.

1 Main St Whitinsville, MA 01588 (Limited pickup in Whitinsville)

800-225-0508

8:30 to 4:30 (EST) Mon through Fri

* Website prices reflect the prices from our default vendors. Occasionally we are unable to obtain the wire from these vendors; substitutions may be available and may result in a higher price. We will inform you of any price difference if this occurs. Prices are subject to change based on current vendor availability and current price of steel. If this occurs we will inform you of any price difference before processing your order.